Resources

Proper Refrigerant Line Sizing for Reliable System Performance.

Ensure Correct Refrigerant Line Sizing

Proper refrigerant line sizing is critical to the performance, efficiency, and reliability of a refrigeration system. Line set dimensions directly affect pressure drop, oil return, and overall system stability, and should never be based solely on the connection sizes provided with the evaporator or condensing unit. Incorrect line sizing can lead to reduced capacity, excessive compressor wear, and long-term system reliability issues.

To ensure accurate line set design, all relevant factors such as system capacity, refrigerant type, line length, vertical rise, and operating conditions must be considered. LRC recommends calculating refrigerant line sizes using proven engineering tools rather than relying on rule-of-thumb assumptions. Please use the line sizing calculator available at HVACRadvisors.com to properly determine the correct line set size for your application.

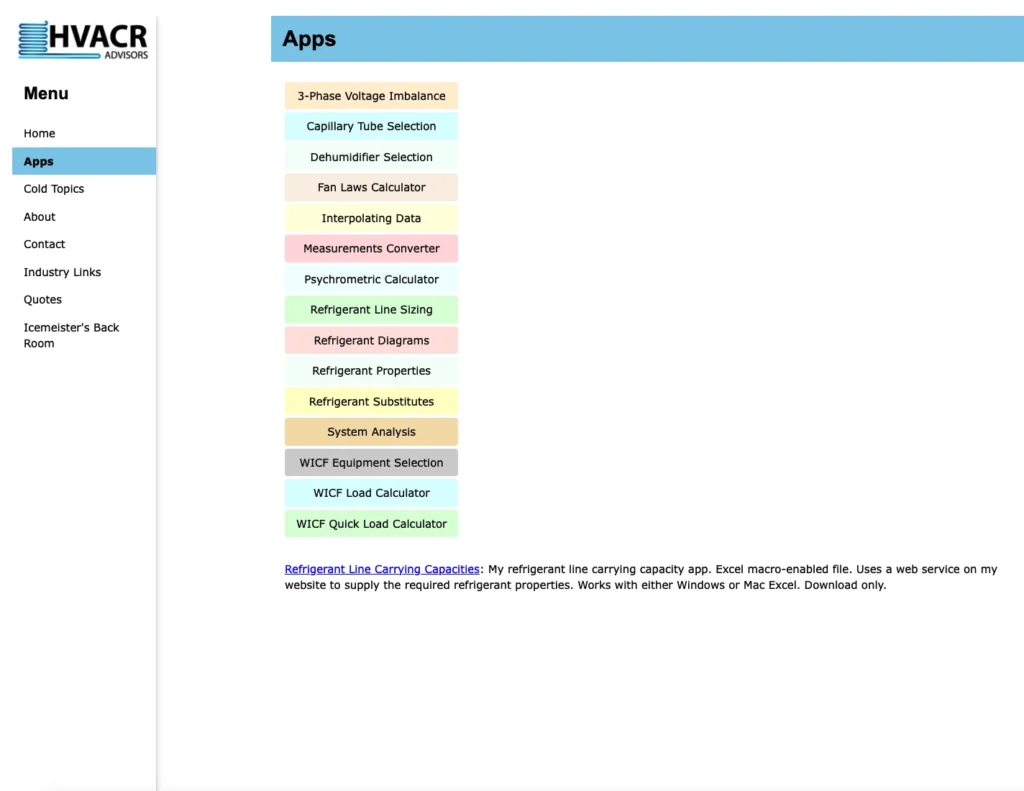

Calculates voltage imbalance in three-phase electrical systems to help identify efficiency losses and potential motor damage.

Assists in selecting the proper capillary tube size based on system capacity and operating conditions.

Helps determine the appropriate dehumidifier capacity required for specific space conditions and moisture loads.

Uses fan laws to predict changes in airflow, pressure, and power when fan speed or size is adjusted.

Provides accurate interpolation between known data points for HVAC and refrigeration calculations.

Quickly converts common HVAC and refrigeration units for temperature, pressure, flow, and power.

Calculates air properties such as humidity, dew point, enthalpy, and wet-bulb temperature for system design and analysis.

Determines proper refrigerant line sizes to ensure correct oil return, pressure drop, and system performance.

Displays pressure-enthalpy and temperature-entropy diagrams to aid in refrigeration cycle analysis.

Provides thermodynamic properties for common refrigerants used in HVAC and refrigeration systems.

Helps identify compatible replacement refrigerants based on performance, pressure, and application requirements.

Evaluates overall refrigeration system performance to identify inefficiencies or improper operating conditions.

Assists in selecting appropriate equipment for walk-in coolers and freezers based on load requirements.

Calculates detailed refrigeration loads for walk-in cooler and freezer applications.

Provides a fast, simplified load estimate for walk-in cooler and freezer sizing.