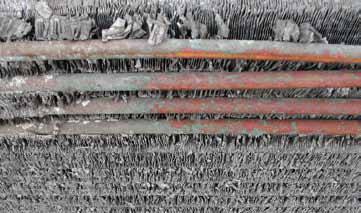

LRC Coating™ – Self Cleaning Coating Formula REPELS FROST

Anti-microbial coil coating actively kills harmful biofilm growth that can lead to airflow contamination.

Environmentally Friendly and Less Expensive LRC Coating™ Protective Coating –

- Dipped/baked, self etching, water based epoxy

- Cures quickly – NO ADDITIONAL BUILD LEADTIME

- Environmentally friendly” high performance resin

- Less expensive than solvent based products

- No Impact on heat transfer or air flow

- Meets FDA/NSF requirements for indirect food applications

Don’t let your equipment corrode in harsh environments. Call LRC Coil today.

Why You Should Recommend LRC Coating Products To Your Customers:

- Stabilizes installed HVAC systems that have been degraded by corrosion, which delays equipment replacement costs

- Coated units are “self cleaning” due to hydrophobic formula which causes moisture/condensate run-off

- “Self cleaning” coils reduce pressure drop due to contamination and corrosion

- Anti-microbial additive kills algae/bacteria which helps maintain clean building air

- Increases equipment life with minimal maintenance

- Water based cleaners and coatings are safe, non toxic and low volatile organic compounds (VOCs)

Hydrophobic (Water Repelling) Protection System

- Leaking wine corks can corrode copper. With LRC Coat™ Protective Coating, coils in wine units are guaranteed to last longer.

- LRC Coat™ will eliminate mold and harmful bacteria to help maintain healthy air inside of the building.

Contact Info

LRC Coating™ – Self Cleaning Coating Formula REPELS FROST Anti-microbial coil coating actively kills harmful biofilm growth that can lead to airflow contamination

Environmentally Friendly and Less Expensive LRC Coat™ Protective Coating – • Dipped/baked, self etching, water based epoxy • Cures quickly – NO ADDITIONAL BUILD LEADTIME • “Environmentally friendly” high performance resin • Less expensive than solvent based products • No Impact on heat transfer or air flow • Meets FDA/NSF requirements for indirect food applications